For years, our industry has relied on traditional metrics such as average face velocity to gauge the safety of laboratory fume hoods. However, recent findings suggest that this method is fundamentally flawed and insufficient for ensuring true safety and effectiveness. I'm reaching out today to discuss a transformative approach to fume hood testing that focuses on what really matters—Containment.

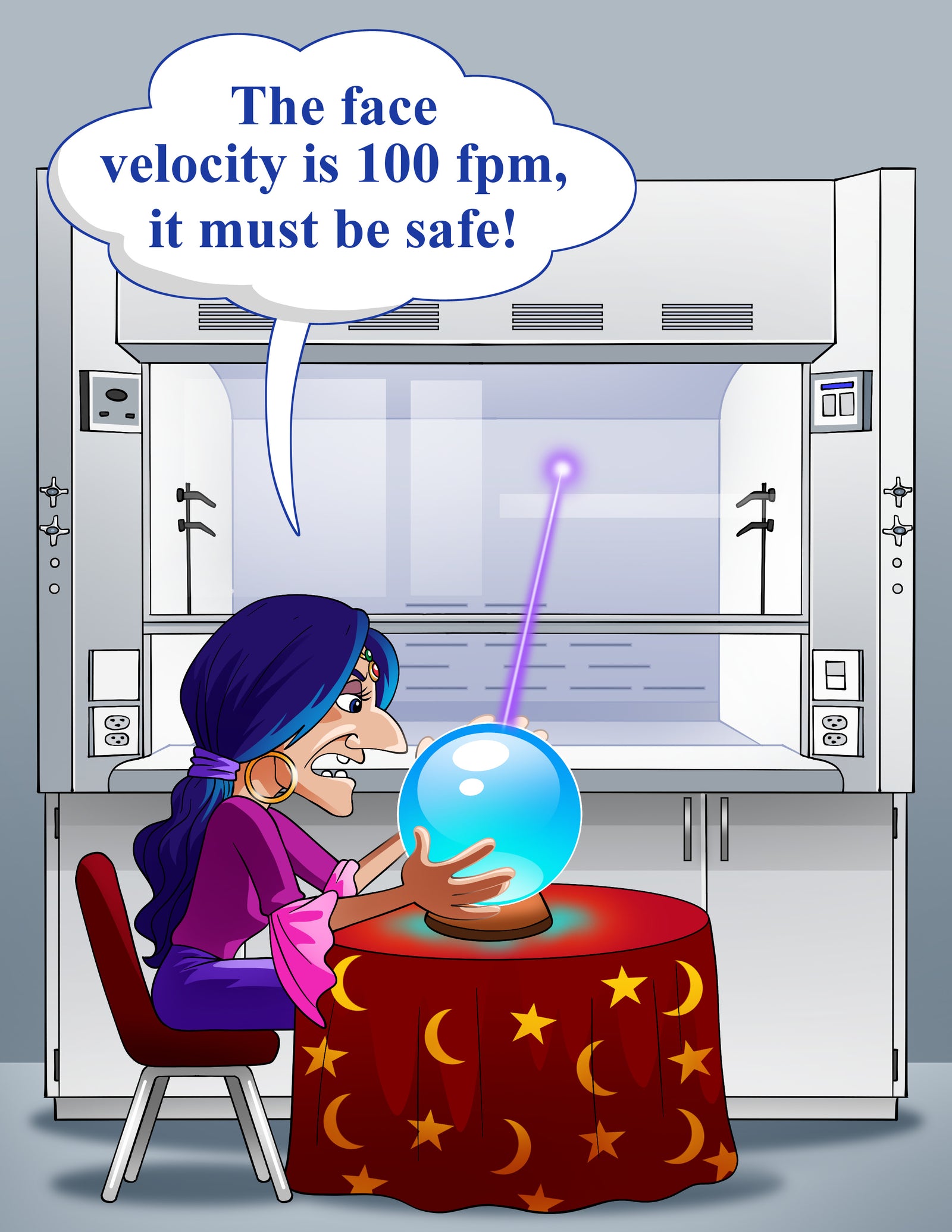

The primary function of a fume hood is an Exposure Control Device. Laboratory personnel rely on fume hoods to provide a safe environment for working with toxic and hazardous substances. A fume hood that loses containment, regardless of its face velocity, is failing its essential purpose. Alarmingly, it has been documented that over 70% of hoods that fail containment testing still report acceptable face velocities, clearly demonstrating that traditional metrics can be dangerously misleading and a huge disservice to the user who generally believe if there is a hood in their lab it is performing safely.

The primary function of a fume hood is an Exposure Control Device. Laboratory personnel rely on fume hoods to provide a safe environment for working with toxic and hazardous substances. A fume hood that loses containment, regardless of its face velocity, is failing its essential purpose. Alarmingly, it has been documented that over 70% of hoods that fail containment testing still report acceptable face velocities, clearly demonstrating that traditional metrics can be dangerously misleading and a huge disservice to the user who generally believe if there is a hood in their lab it is performing safely.

If you wanted to measure the velocity and direction of the flow, where would you take your reading?

The average face velocity has long been the industry accepted way to assess fume hood performance. Yet, this metric alone is proving to be inadequate. True performance is largely influenced by turbulence not face velocity. Fume hoods are very turbulent, and the degree of turbulence is influenced by many factors such as the stability of the exhaust system, the room conditions and even the users’ work practices. Average Face Velocity gives a false sense of security, overlooking critical performance failures that could jeopardize user safety. Just having a fume hood in a lab doesn't guarantee its safely performing.

This is where dynamic containment testing comes into play. Unlike static tests, dynamic containment testing evaluates the fume hood's performance under actual working conditions—mimicking the movements, equipment, and procedures typical of daily laboratory operations. This method not only highlights the existing vulnerabilities but also provides actionable insights into how the fume hoods can be optimized for better safety.

Tri-Color Airflow Visualizer is a game changer. It is highly visual which means you can clearly see if your hood has containment problems. We believe that if you can’t see a problem, you can’t fix it. And unlike some of the expensive test procedures, Tri-Color is safe, simple and economical at only pennies per hood. It fact it is so simple a fifth grader can and has done it.

We at Fume Hood Certified are advocating for this shift towards dynamic containment testing as the new standard. Our extensive research and field tests have consistently shown that this approach not only enhances the understanding of a fume hood’s operational safety but also significantly reduces the risk of exposure to harmful substances. And it is not just a testing method, it is an educational tool that helps the user how what they do in and around the hood impact performance.

Implementing dynamic containment testing could revolutionize safety protocols in laboratories worldwide, ensuring that personnel are not just relying on outdated metrics, but are supported by a testing method that truly corresponds to their daily challenges and needs. Currently Tri-Color is being used in 6 countries.

We are committed to advancing laboratory safety one fume hood at a time. Join us on this exciting journey.

Let's set a new standard together—one that genuinely protects our laboratory professionals.

Thank you for considering this pivotal enhancement to laboratory safety standards. I look forward to your thoughts and hope to collaborate closely with you to champion this crucial initiative. We have assembled a collection of reference documents to make it easy for you to learn more. Please check it out. Click Here.

The average face velocity has long been the industry accepted way to assess fume hood performance. Yet, this metric alone is proving to be inadequate. True performance is largely influenced by turbulence not face velocity. Fume hoods are very turbulent, and the degree of turbulence is influenced by many factors such as the stability of the exhaust system, the room conditions and even the users’ work practices. Average Face Velocity gives a false sense of security, overlooking critical performance failures that could jeopardize user safety. Just having a fume hood in a lab doesn't guarantee its safely performing.

This is where dynamic containment testing comes into play. Unlike static tests, dynamic containment testing evaluates the fume hood's performance under actual working conditions—mimicking the movements, equipment, and procedures typical of daily laboratory operations. This method not only highlights the existing vulnerabilities but also provides actionable insights into how the fume hoods can be optimized for better safety.

Tri-Color Airflow Visualizer is a game changer. It is highly visual which means you can clearly see if your hood has containment problems. We believe that if you can’t see a problem, you can’t fix it. And unlike some of the expensive test procedures, Tri-Color is safe, simple and economical at only pennies per hood. It fact it is so simple a fifth grader can and has done it.

We at Fume Hood Certified are advocating for this shift towards dynamic containment testing as the new standard. Our extensive research and field tests have consistently shown that this approach not only enhances the understanding of a fume hood’s operational safety but also significantly reduces the risk of exposure to harmful substances. And it is not just a testing method, it is an educational tool that helps the user how what they do in and around the hood impact performance.

Implementing dynamic containment testing could revolutionize safety protocols in laboratories worldwide, ensuring that personnel are not just relying on outdated metrics, but are supported by a testing method that truly corresponds to their daily challenges and needs. Currently Tri-Color is being used in 6 countries.

We are committed to advancing laboratory safety one fume hood at a time. Join us on this exciting journey.

Let's set a new standard together—one that genuinely protects our laboratory professionals.

Thank you for considering this pivotal enhancement to laboratory safety standards. I look forward to your thoughts and hope to collaborate closely with you to champion this crucial initiative. We have assembled a collection of reference documents to make it easy for you to learn more. Please check it out. Click Here.